The transition to lower-global warming potential (GWP) refrigerants hit a new milestone this year in the U.S. air-conditioning sector. Since January, all new residential and light commercial air-conditioning equipment has been required to use refrigerants with a global warming potential (GWP) below 700 — ushering in the era of A2Ls. While these refrigerants represent a sustainable step forward, they also raise complex questions for contractors and HVAC technicians.

One question that stands out is: Should you recommend repairing existing equipment, or is replacement the better course of action?

This decision impacts the homeowner’s budget and factors in long-term energy efficiency and environmental responsibility, among other key considerations. Here’s what you need to know to guide your clients effectively and ensure you provide solutions that align with today’s market demands.

Understanding the emergence of A2Ls

The global transition from high-GWP hydrofluorocarbon (HFC) refrigerants is underway. A2L refrigerants, which are mildly flammable yet more sustainable, are becoming the industry standard. These refrigerants comply with the GWP limit of 700, as mandated by the Environmental Protection Agency’s (EPA) Technology Transition rule under the authority of the American Innovation and Manufacturing Act (AIM Act).

The implications of A2L adoption are widespread for residential HVAC systems. Systems designed for legacy refrigerants are not compatible with A2Ls, primarily due to their flammability and resultant safety requirements. However, the transition to A2L refrigerants in the AC sector won’t happen overnight. Existing R-410A equipment will still need to be serviced for many years throughout their useful lifecycles.

This raises the question of whether a repair is practical or if a full system replacement would be more beneficial. Technicians must be prepared to provide homeowners with their options

When to recommend repairing existing equipment

Repairing existing HVAC equipment may seem the most economical option for homeowners, but this decision relies on several factors.

System age and condition — If the system is still in good physical condition, repairs can extend its lifespan while allowing the homeowner to budget for a future upgrade. Be cautious with older systems, as the cost of repeated repairs may exceed the expense of a new system designed for A2Ls.

Refrigerant availability and cost — Legacy refrigerants like R-410A may become more expensive as phasedown efforts begin to limit supply. If a repair requires recharging with R-410A, discuss the current and potential future costs with the homeowner.

Relative energy assessment — Evaluate the energy efficiency difference between legacy and new A2L systems, especially since older systems may be experiencing significant energy losses. With new A2L systems designed to meet the Department of Energy’s (DOE) minimum system efficiency standards that were updated in January 2023, upgrading from an energy efficiency standpoint may prove beneficial in the long run.

While temporary repairs may be a suitable stopgap for homeowners not ready to commit to a system replacement, modern HVAC systems are far more energy-efficient than systems installed several years ago. They can reduce monthly energy bills while migrating to a lower-GWP refrigerant.

Additionally, end users may be able to offset replacement costs with available incentives and tax rebates. Check state programs, federal tax credits, local utility incentives, and manufacturer rebates.

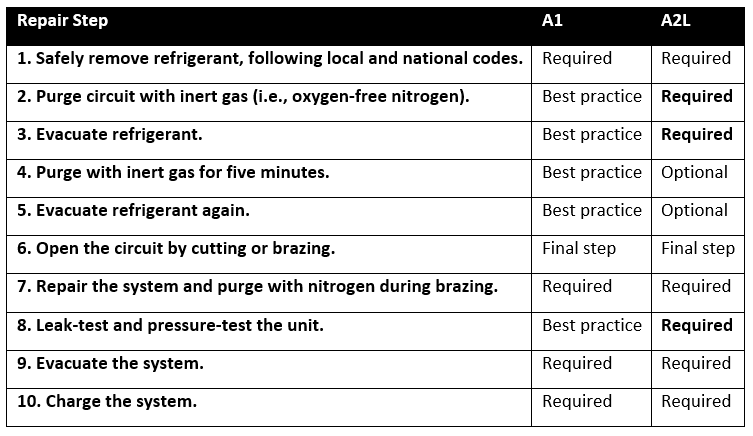

A2L servicing best practices

Despite any reservations and concerns about servicing A2Ls, specific best practices are the same as those currently used. Most are rules of thumb that technicians already know but have not always been required to follow with R-410A systems, including:

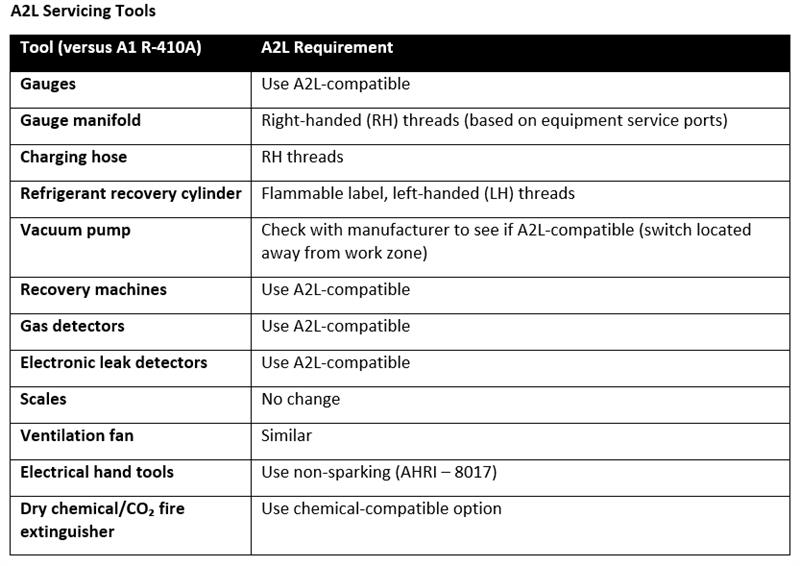

Technicians must use only A2L-certified tools/gauges, replacement parts, leak detection, components and compressors. Note that threading and labeling are unique to A2Ls to ensure differentiation from R-410A.

As a rule, it’s important to remember that fluids and components are not interchangeable — both among new and legacy equipment and specific A2L refrigerant blends. For example:

- Do not charge an R-410A system with an A2L refrigerant (or vice versa).

- Do not charge an R-454B system with R-32 refrigerant (i.e., two different A2Ls).

- R-410A compressors or components are incompatible in an A2L-optimized system (and vice versa).

- In A2L systems requiring leak detection, devices and/or sensors must be optimized to detect a specific A2L refrigerant (i.e., R-454B or R-32).

Be aware that mitigation measures, often including leak detection, will be mandatory on A2L units above ~4 pounds of charge. If needed, refrigerant detection devices and sensors will most likely be placed on or near the evaporator coil, where leaks commonly occur. Note: these devices and/or sensors must also be optimized to detect the system’s specific A2L refrigerant.

Take the worry out of the A2L refrigerant transition.

For several years, Copeland has prepared for the emergence of A2L refrigerants in new residential equipment. With the EPA rule now in effect, HVAC technicians are beginning to see these units in the field. Whether you’re installing a new A2L system or repairing a legacy R-410A unit, Copeland is here to help protect your reputation and uphold your high-reliability standards. Our A2L-optimized compressors are among the most efficient and reliable found in AC and heat pump equipment; and our R-410 compressors will still be available to repair existing systems.

If you’re an HVAC technician seeking more information on safely installing, servicing, and recovering A2L refrigerants, Copeland’s Educational Services team conducts in-person and online A2L training seminars.

For more information on A2L refrigerants, please visit Copeland’s A2L resource center for a complete repository of webinars, videos, white papers, articles, and blogs covering the transition to next-gen refrigerants.

Facility Health Score Insights Program Transforms Enterprise Maintenance

Leveraging refrigeration performance data drives food retail cost reductions. Maintaining proper...

8 proven strategies for rigorous cold chain management

Preparing for the approval and safe use of A2Ls in commercial refrigeration applications...

Protection for high-value shipments just got even better

We’re excited to announce the release of Copeland’s newest real-time tracker, the GO Real-Time...