*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company – Copeland. Though our name has changed, we are building on more than a century of HVACR innovation and industry leadership, and Copeland continues to offer the same products, industry stewardship, and learning opportunities you’ve grown to trust. Information found on this webpage posted before June 1, 2023 may contain our old name or branding, but you can be at ease knowing it was created with the knowledge and expertise of Copeland.

Changing refrigeration technologies and labor shortages are creating a variety of challenges for operators of supermarkets, pharmacies, and dollar and convenience stores (c-stores). These concerns call for modern tools that can help you meet disparate objectives without sacrificing food quality, safety or customer experiences.

In a recent article, we explored five ways connected, cloud-based internet of things (IoT) technologies are evolving to address nearly every facet of chain store operations by simplifying store operations, automating labor-intensive tasks, and streamlining enterprise management. Although most retailers recognize the need for creating an IoT-enabled enterprise, many don’t understand the full scope of its benefits — or even how to get started.

Copeland has responded by partnering with retailers to streamline digital transformation, improve operational efficiencies, and deliver substantial return on investment (ROI). These benefits are made possible by Copeland’s Connect+ enterprise software, combined with the site supervisor controller, all-new E3 supervisory control platform for refrigeration and complete facility management and legacy E2 controller — which collectively create the robust, always-on IoT infrastructure retailers need to take control of their entire store network.

Here’s a quick summary of the top five ways this robust IoT toolset is helping retailers reach their operational goals.

- Faster issue resolution

Centralized enterprise software with robust alarm management gives facility managers the tools to quickly identify issues and prioritize resolution — in individual facilities and across their multi-site network of stores. Store operators and service technicians can rapidly drill down to individual stores, assets and component-level status data to examine root causes and accelerate resolutions.

- Optimized system performance via continuous commissioning

Most systems gradually drift from ideal setpoints and design conditions after commissioning — resulting in increased energy consumption, declining food quality and rising operational costs across multi-site enterprises. The setpoint management feature in Connect+ is designed to continually preserve setpoint optimization after the initial commissioning process — even across hundreds or thousands of stores — notifying service personnel when further investigation or corrective action is needed.

- Predictive maintenance

Instead of waiting for problems to result in equipment failure or conducting preventive maintenance on a predetermined schedule, Connect+ software leverages decades of refrigeration experience to enable early detection of performance issues. As these exceptions are detected, it issues mobile alerts to designated service personnel to help you quickly triage, diagnose and fix issues. Over time, performance data aggerates into an ever-expanding library of datasets, supporting and informing true predictive maintenance.

- Protect food quality and safety

Connect+ software helps you automate monitoring and reporting processes to provide comprehensive data on refrigeration factors contributing to food quality and safety. This frees up large amounts of employee time and eliminates the errors common in manual reporting. In addition, the food quality reports (FQR) feature helps you spot deviations from acceptable limits, document defrost cycles, and implement hazard analysis and critical control points (HACCP) methodologies.

- Optimize enterprise energy efficiencies

Connect+ was designed with robust capabilities to address the challenges of managing energy consumption across an entire store network. Its multi-site outlier management tool helps you quickly identify which stores are exceeding their corporate energy efficiency standards at any given moment. An intuitive dashboard guides end users and operators through the process of finding and fixing outliers.

Paired with Connect+ software, the E3 controller can function as a robust energy management system, enabling the connectivity needed to participate in demand response/curtailment programs with local utilities while supporting grid interactive building (GIB) and distributed energy resource (DER) models.

Partner with experts in enterprise optimization

Through Copeland’s Connect+ enterprise management software, E3 supervisory control platform, supporting cloud infrastructure and domain expertise, we’re helping multi-site retailers build foundations for continuous improvement across their enterprises.

Read the full article for more details about how we can help your enterprise build out its IoT infrastructure, and drive facility automation, energy efficiency and refrigeration reliability.

Six Ways to Reduce Food Waste by Tracking the Supply Chain

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

Protect Valuable Shipments in High-Crime Areas

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

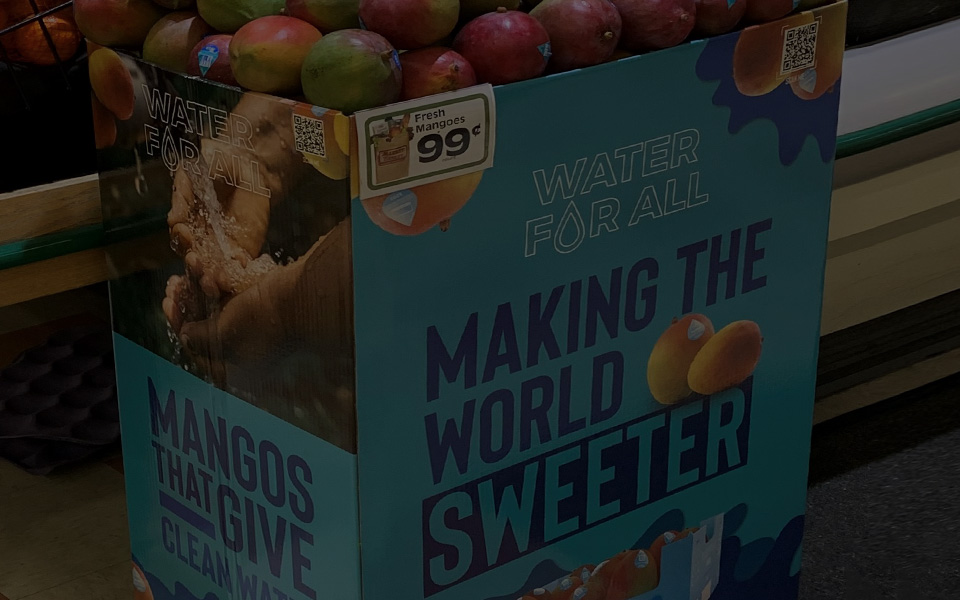

Real-time Tracking Protects Valuable Mango Cargo

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...