*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company – Copeland. Though our name has changed, we are building on more than a century of HVACR innovation and industry leadership, and Copeland continues to offer the same products, industry stewardship, and learning opportunities you’ve grown to trust. Information found on this webpage posted before June 1, 2023 may contain our old name or branding, but you can be at ease knowing it was created with the knowledge and expertise of Copeland.

In 2019, Emerson hosted an in-depth E360 panel discussion on automating the commercial kitchen. The panelists, a cross-section of industry experts, proposed valuable insights on the potential that automation and connectivity offer commercial restaurants. In the second article of this three-part series, I summarize their thoughts on building the business case for internet of things technologies and tackling common challenges. You can read the full article here.

Internet of things (IoT) technologies are steadily making inroads in the commercial kitchen landscape. And that’s posing a set of challenging questions for quick-service restaurants (QSR) eager to benefit from the cost savings and improved quality control that a connected kitchen can deliver.

For this reason alone, building a sound business case for IoT technologies is critical. The process is an excellent opportunity to tackle difficult questions at the front end to avoid costly pitfalls during — and after — implementation.

Ensuring data is actionable

As we discussed in our first article in this series, IoT technologies offer tremendous potential to reduce labor costs and improve food safety. But before QSRs invest in new technologies, they must first ask how serious their operators are about actually using data.

This is one of the most important questions to ask, because applicability must always be the defining feature of every IoT investment. As more equipment comes online and the number of data points expands, store managers will have access to a staggering amount of data that they don’t have the time or skillset to interpret. To be useful, the data must be paired with simple alerts or other actionable information that operators can quickly and easily act upon.

Determining data ownership

As they build their business cases, QSRs must also determine who will own the data. Most often, this will be the foodservice corporation, the franchisee or the original equipment manufacturer (OEM). Issues can arise when the owner of the data doesn’t see much advantage in sharing with others.

However, making the data accessible to all three parties may prove beneficial to each. Sharing information between the corporation and the franchisee could identify new avenues for cost savings. OEMs could use the information to make ongoing improvements to their equipment. And opening up access to source and derived data could lead to a reduction in service calls and lower service warranty costs.

Simplifying the user experience

The user interface is another consideration that QSRs need to factor in early on. Most QSRs source their equipment from multiple manufacturers, which makes uniformity a challenge. Any efficiencies captured through connected equipment could potentially be undone if operators are forced to log into and navigate multiple interfaces in order to access data.

Some QSRs, such as Wendy’s, are creating custom interfaces which share a common look and feel. This allows employees to share the same user experience, no matter which equipment interface they are accessing. Conversely, QSRs can opt to invest in a common interface that consolidates data for all equipment types and brands in one place, under one login.

Room for improvement

One area that still needs refinement is servicing. IoT technologies should be providing technicians with a trove of information. Yet whether it’s because the data is too siloed or because IoT is relatively underdeveloped in commercial kitchens, the benefits to servicing are falling short. Still, as the technology matures, productivity gains for servicing and maintenance will come to light as well.

Emerson’s product development expertise is moving the industry closer to a true plug-and-play approach by simplifying connectivity and developing application program interface (API) strategies. Our goal is to provide intuitive, streamlined access and information that operators can act upon so they can achieve their business objectives, protect their brands, and drive greater cost savings.

In the next and final article in this series, we’ll delve into the future of automation in the commercial kitchen and dig into the emerging challenges of data security and connectivity protocols.

Six Ways to Reduce Food Waste by Tracking the Supply Chain

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

Protect Valuable Shipments in High-Crime Areas

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

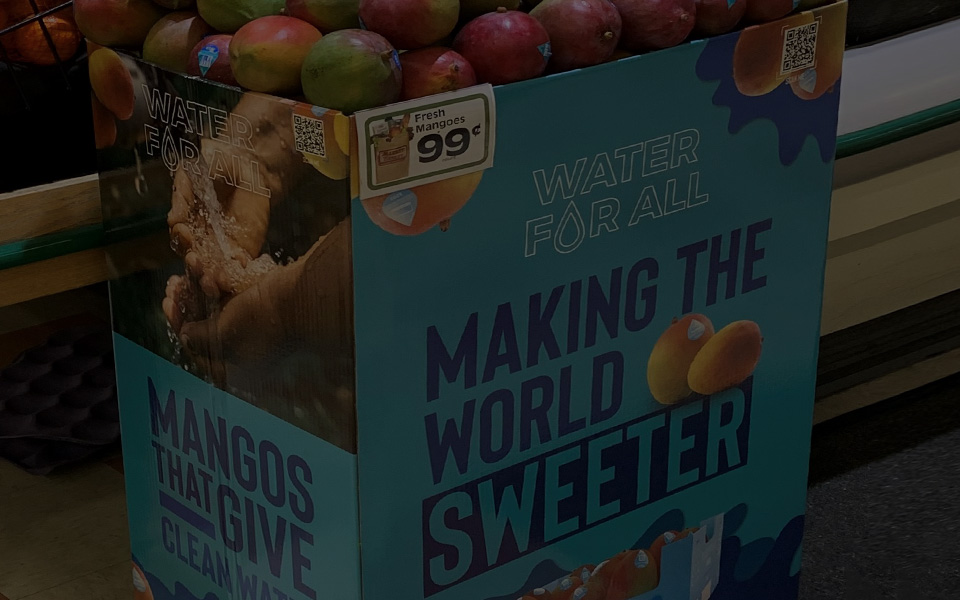

Real-time Tracking Protects Valuable Mango Cargo

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...