*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company – Copeland. Though our name has changed, we are building on more than a century of HVACR innovation and industry leadership, and Copeland continues to offer the same products, industry stewardship, and learning opportunities you’ve grown to trust. Information found on this webpage posted before June 1, 2023 may contain our old name or branding, but you can be at ease knowing it was created with the knowledge and expertise of Copeland.

The regulatory wheels are in motion driving the migration from legacy hydrofluorocarbon (HFC) refrigerants to lower-global warming potential (GWP) alternatives. In both refrigeration and AC sectors, federal- and state-led regulations — combined with industry codes and standards makers — are actively preparing for the next generation of system and equipment technologies. As compliance and HFC phasedown timelines approach quickly, it’s critical to stay informed and understand the impacts they may have on your business. In a recent E360 Webinar, Dr. Rajan Rajendran, Copeland’s global vice president of environmental sustainability and I surveyed the latest changes to the refrigerant regulatory landscape.

The regulatory wheels are in motion driving the migration from legacy hydrofluorocarbon (HFC) refrigerants to lower-global warming potential (GWP) alternatives. In both refrigeration and AC sectors, federal- and state-led regulations — combined with industry codes and standards makers — are actively preparing for the next generation of system and equipment technologies. As compliance and HFC phasedown timelines approach quickly, it’s critical to stay informed and understand the impacts they may have on your business. In a recent E360 Webinar, Dr. Rajan Rajendran, Copeland’s global vice president of environmental sustainability and I surveyed the latest changes to the refrigerant regulatory landscape.

EPA takes “AIM” at the HFC phasedown

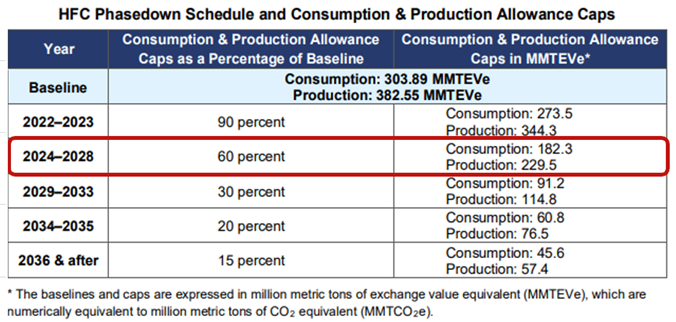

The 2020 passing of the American Innovation & Manufacturing Act (AIM Act) gave the Environmental Protection Agency (EPA) the authority to regulate HFCs, aligning its mandate with the global HFC phasedown outlined in the Kigali Amendment to the Montreal Protocol. The next steps in these HFC phasedowns are fast approaching, with a 40 percent reduction in consumption and production set for 2024, and a 70 percent reduction in 2029. Since these steps are relative to a 2013 baseline — and HFC reductions have been ongoing since then — actual reductions may be even lower. This progressive reduction in HFC supplies will significantly impact the current/legacy equipment install base, placing a greater emphasis on refrigerant reclamation and driving up prices.

EPA proposes Technology Transitions rule

In late 2022, the EPA proposed a Technology Transitions rule that would impose new GWP limits across HVACR sectors. Although it mostly aligns with Air-Conditioning, Heating, and Refrigeration Institute (AHRI) recommendations, the proposed compliance dates are set to begin in 2025 — one year earlier than expected. Proposed GWP restrictions per sector include:

- Commercial refrigeration: 150 GWP in large systems (≥200 lbs.) and self-contained units; 300 GWP in smaller-charge systems (<200 lbs.)

- Cold storage warehouses and industrial refrigeration: 150 GWP in large systems (≥200 lbs.) and self-contained; 300 GWP in smaller-charge systems (<200 lbs.)

- Automatic commercial ice machines: 150 GWP (≤500 grams)

- Chillers used in industrial process refrigeration and comfort cooling: 700 GWP

- Residential and light commercial AC and heat pump systems: 700 GWP

A final rule of EPA’s Technology Transition proposal is expected in October.

New EPA standards for HFC management

As HFC supplies decrease, preserving the current HFC reserves in existing equipment will be increasingly important to the service market. The EPA is working to establish new standards for HFC management that would include mandates for reclamation, leak repair and servicing best practices. Recent EPA estimates point to the importance of proper reclamation procedures:

- Less than 2 percent of HFCs are reclaimed.

- 86 percent of HFCs are used in refrigeration, AC and heat pumps.

- 60 percent of HFCs are used to top up leaks.

In addition to being an environmental best practice, effective management of HFCs during the refrigerant transition will be needed to maintain supplies, minimize disruption in current stocks of HFC equipment, and avoid the broad impacts of market shortages.

A2L approvals are forthcoming in SNAP 26

In tandem with the Technology Transitions proposal, the EPA is actively reviewing new alternatives under its Significant New Alternatives Policy (SNAP) program. Thus, as legacy HFCs are phased out, emerging alternatives can be phased in. Among these include lower-flammability A2L refrigerants — which can be used in both self-contained and remote applications — and larger charges of the higher-flammability A3, R-290 in self-contained units. Previous SNAP rules have approved A2Ls for use in light commercial AC and heat pump applications and R-290 in self-contained refrigeration with less than 150 grams. Safety standards have already laid the groundwork for establishing the safe product development and applications standards for these lower-GWP applications.

We expect SNAP Rule 26 to be announced this summer.

Evolving standards and codes for flammable refrigerants

Because compliance with expected lower-GWP limits will require the use of flammable refrigerants, safety standards and building codes are actively evolving to permit their use. These standards help to establish safe use requirements, charge limit guidelines, and application and installation standards, including:

- UL 60335-2-89, 2nd edition product safety standard (2021) includes provisions for the use of A2L refrigerants and increased charges of R-290 in commercial refrigeration.

- UL 60335-2-40, 4th edition product safety standard (2022) enables use of lower-GWP A2L alternatives in comfort cooling and heating.

- ASHRAE 15, Addendum L application standard (2022) specifies safety mitigations and restrictions for installation locations, application and equipment based on occupancy type.

Industry organizations are working to harmonize these standards for clear and consistent application across sectors.

Building codes — which are proposed and adopted at state and/or local levels — are among the steps needed to enable the use of lower-flammability A2L refrigerant alternatives. Because building codes are tied to model codes — which are updated on three-year cycles in the best-case scenario — pushing through the approvals needed to support widespread A2L adoption is becoming a top industry priority. AHRI is taking the lead on engaging states to update their building codes, but there is still much work to be done. To date, fewer than 20 states have approved A2Ls for both AC and refrigeration.

State-led efforts continue with Climate Alliance

Of course, refrigerant regulations are not limited to federal activity. Driven by individual decarbonization scoping plans and sustainability road maps, many states are continuing their efforts to accelerate the transition to lower-GWP refrigerants. This includes the 25 members of the U.S. Climate Alliance — which represents more than half of the country’s gross domestic product (GDP) — whom have largely adopted the EPA’s original SNAP Rules 20 and 21.

The California Air Resources Board (CARB) is exploring “ultra-low-GWP” limits (<30 GWP) as well as servicing bans that would introduce a timeline for reducing refrigerant GWPs over the next decade. Though well-intended, individual, state-led regulations add complexity to an already dynamic regulatory landscape. A standardized, consistent and federally led approach would simplify refrigerant migrations nationwide while benefiting most stakeholders in the commercial refrigeration and AC supply chains.

Although much of the webinar focused on refrigerant regulations, it’s important to also consider that the Department of Energy (DOE) is actively developing next-generation efficiency minimums for refrigeration and AC equipment. As these proposals are introduced, Copeland will provide guidance on their implications.

With all the activity taking place across the regulatory landscape, Copeland remains committed to helping our customers through this important refrigerant transition and keeping the industry informed of the latest rulemaking. For more information, please view this free webinar and visit the regulations section of our content hub.

8 proven strategies for rigorous cold chain management

Preparing for the approval and safe use of A2Ls in commercial refrigeration applications...

Protection for high-value shipments just got even better

We’re excited to announce the release of Copeland’s newest real-time tracker, the GO Real-Time...

Three proven strategies to prevent cargo theft

The over-the-road (OTR) transport industry is experiencing a surge in cargo thefts. As thieves...