*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company – Copeland. Though our name has changed, we are building on more than a century of HVACR innovation and industry leadership, and Copeland continues to offer the same products, industry stewardship, and learning opportunities you’ve grown to trust. Information found on this webpage posted before June 1, 2023 may contain our old name or branding, but you can be at ease knowing it was created with the knowledge and expertise of Copeland.

In post six of our CO2 as a Refrigerant blog series, I will compare CO2 to traditional and emerging refrigerants.

CO2 has been an approved refrigerant in the U.S. for nearly a decade. Today, as the HVACR industry accelerates the transition away from legacy hydrofluorocarbon (HFC) refrigerants with high-global warming potential (GWP), CO2 adoption is on the rise. The future refrigerant landscape is beginning to take shape, with CO2 and other lower-GWP refrigerant alternatives poised to play key roles — each filling a likely niche in terms of application or architectural potential.

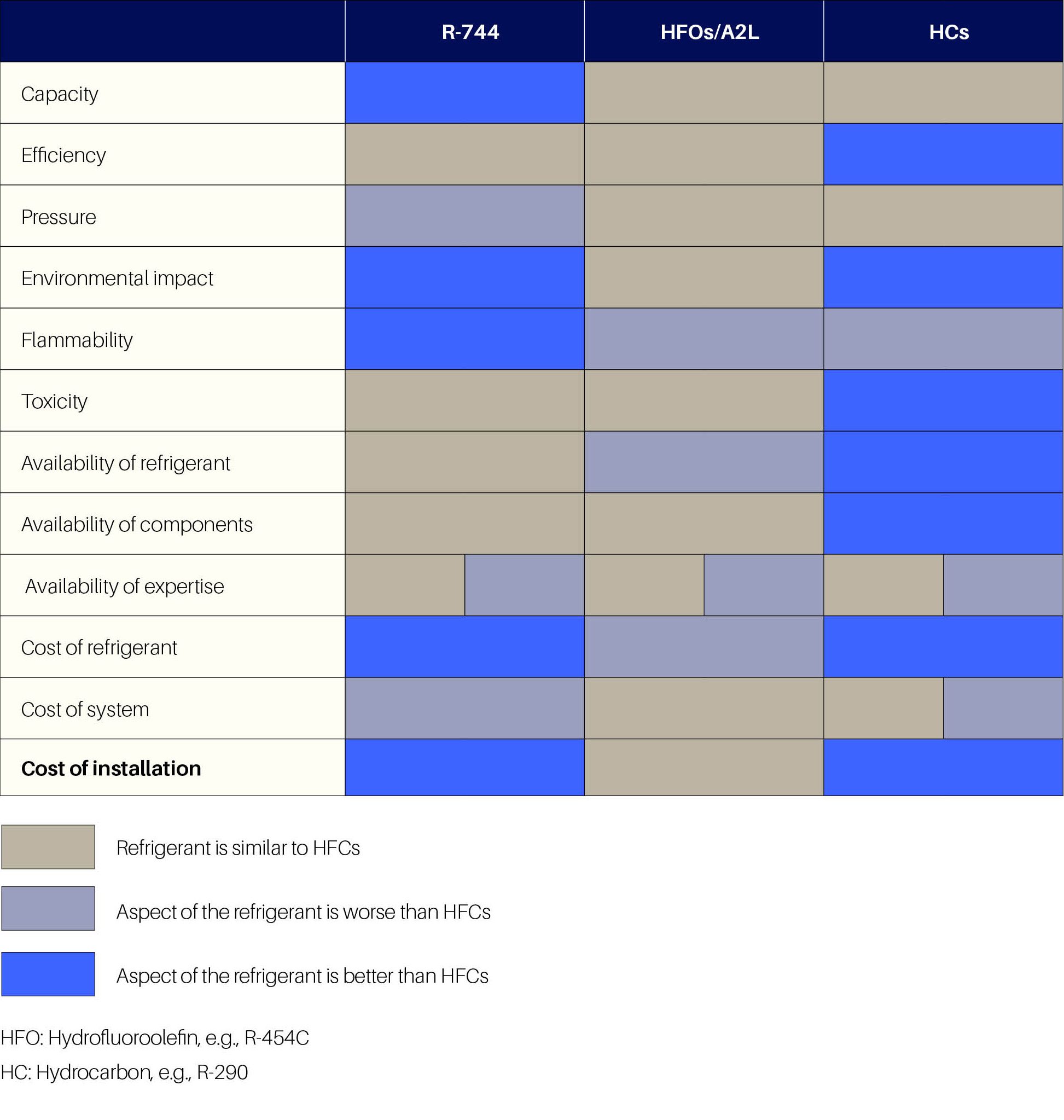

From smaller-charge, self-contained units to condensing units and remote systems to large supermarket racks, R-290, CO2 (R-744) and A2L refrigerants all have their place. Evolving refrigerant regulations and safety standards have also helped to shape these applications, establishing charge limits for R-290 (an A3 with a higher flammability classification) and emerging A2L options (with a lower flammability classification).Table 1 shows a comparison of R-744 with other refrigerants, including legacy hydrofluorocarbon (HFC) refrigerants and emerging A2Ls (i.e., hydrofluoroolefin [HFO] refrigerants) that are currently proposed for use in commercial refrigeration. It uses a simple “traffic light” system and employs common HFCs, such as R-404A and R-134a, as a baseline.

Table 1: Comparison of R-744 with other refrigerants

For many retail applications, a well-designed and installed R-448A/R-449A system generally has better efficiency in higher ambient regions than a base R-744 and/or CO2 booster system with a dry gas cooler. However, the overall environmental performance of R-744 systems aligns with global sustainability and HFC phasedown goals, primarily due to its low-GWP impact in the event of refrigerant leaks.

Note: CO2 system design optimization strategies are now available to improve system efficiencies in high ambient regions. Thus, retailers can implement low-GWP CO2 refrigeration while maintaining energy efficiencies.

Although this overview provides a basic introduction to the leading refrigerant options, global refrigerant availability and regional preferences could impact selection of components and servicing expertise.

Blog post seven in this CO2 as a Refrigerant series will weigh the advantages and disadvantages of R-744.

State-level decarbonization efforts ramp up

New York continues its climate policies in the face of federal deregulation. I recently returned...

Repair or Replace? How to advise homeowners on the shift to A2L refrigerants

The transition to lower-global warming potential (GWP) refrigerants hit a new milestone this year...

Celebrating World Refrigeration Day 2025

Electrical component considerations for A2L system safety Heating, ventilation, air conditioning...